Design

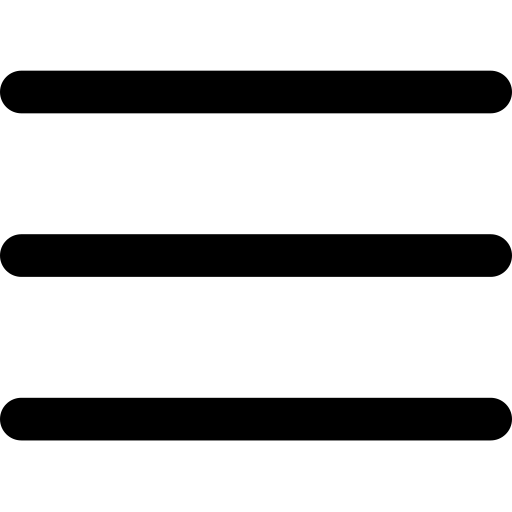

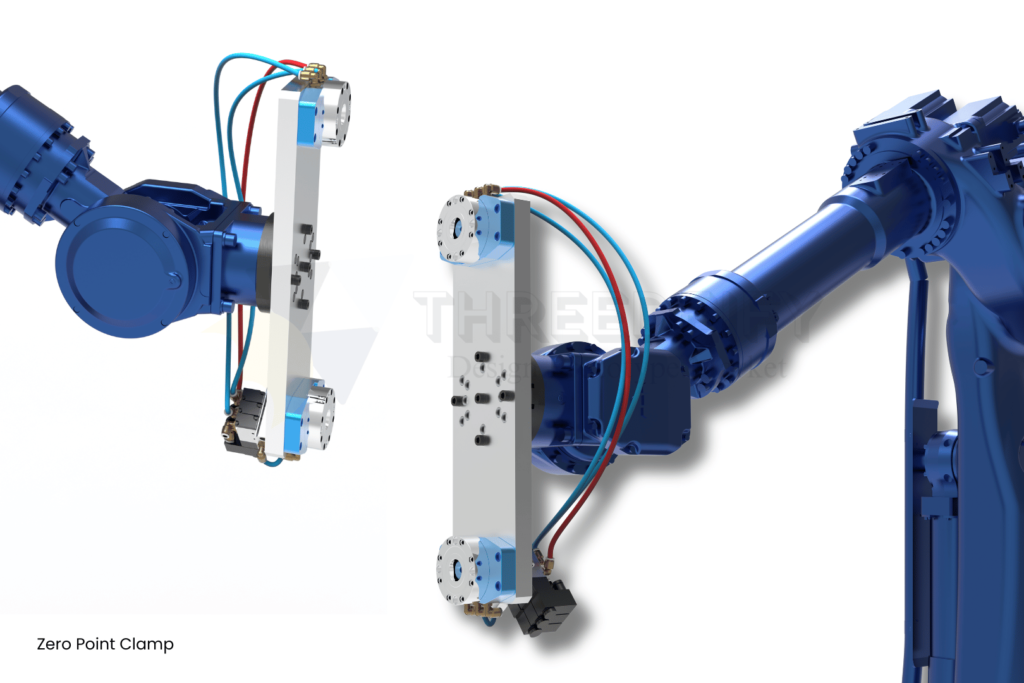

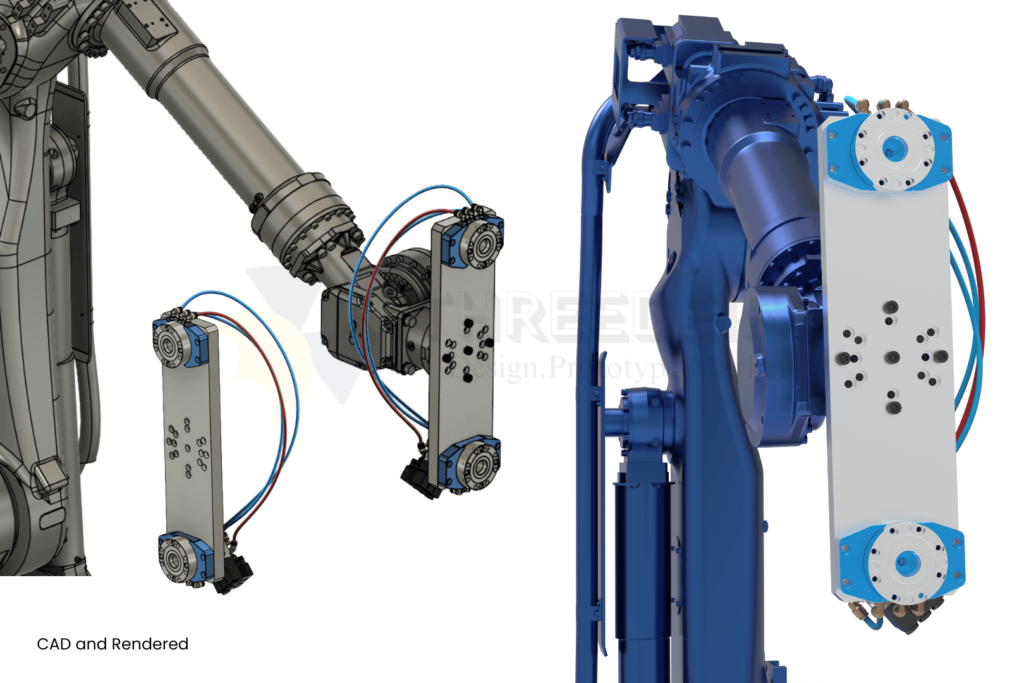

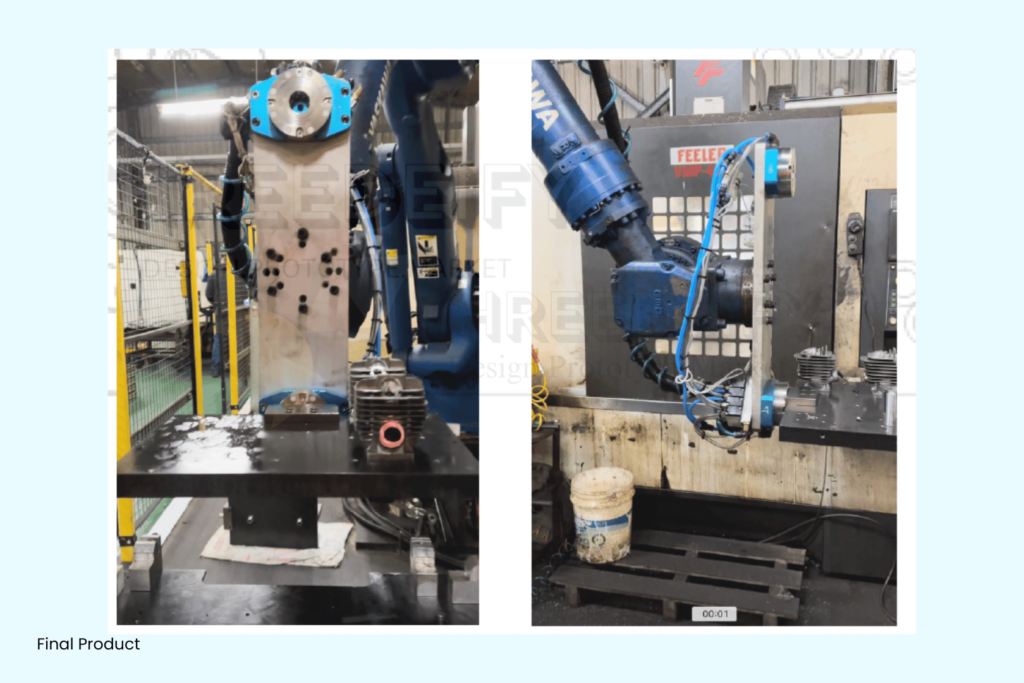

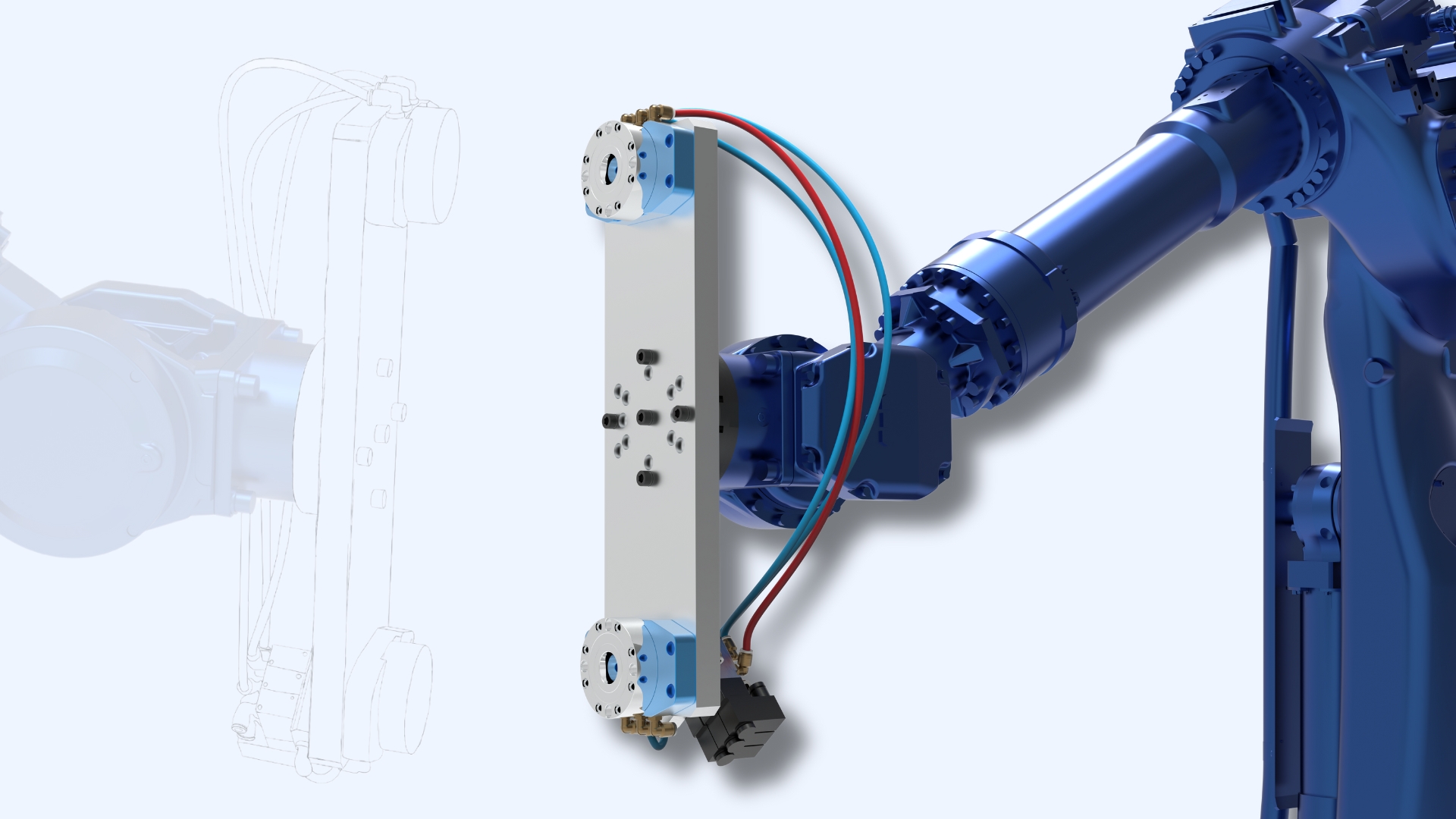

Zero Point Clamp End Arm

Timeline

2022

Client

Wiswig Factory

Services Provided

- Mechanical concepting and design

- Design for manufacturing

- 2D Drawings

- Manufacturing support

Project Summary

Problem Statement

Wiswig Factory approached us with the vision of creating a robust and efficient end effector for their automation processes. Their goal was to develop a solution that securely holds parts during machining and automation tasks. They needed a precise mechanism with retractable zero-point clamps for maximum flexibility and accuracy. The challenge was to design a tool that would enhance their operational efficiency without compromising on precision.

Delivery

Final Outcome

We provided Wiswig Factory with comprehensive support, starting with mechanical concepting and design. Our team developed a zero-point clamp end effector featuring two 180-degree clamps, ensuring optimal part holding during automation. The design included retractable nipples and fast-closing clamps for secure part handling. We completed the project with design-for-manufacturing services, detailed 2D drawings, and ongoing manufacturing support. The final product not only met the client’s needs but also boosted operational precision and reduced production time by improving the automation process.