Design

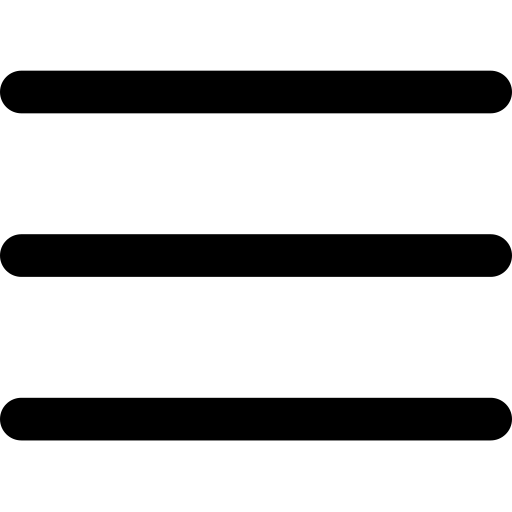

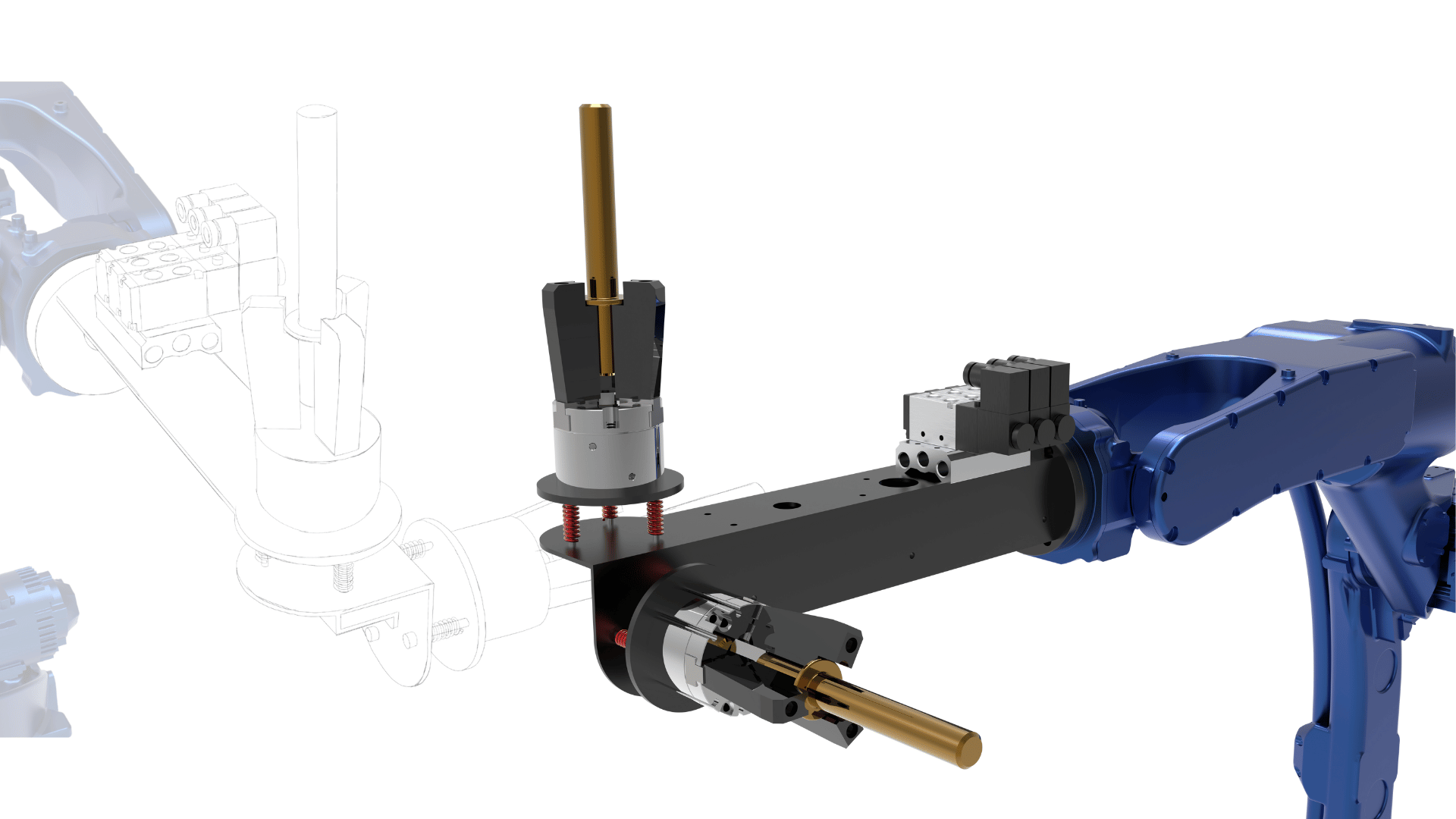

HFCY50 GP12 End Effector

Timeline

2023

Client

Wiswig Factory

Services Provided

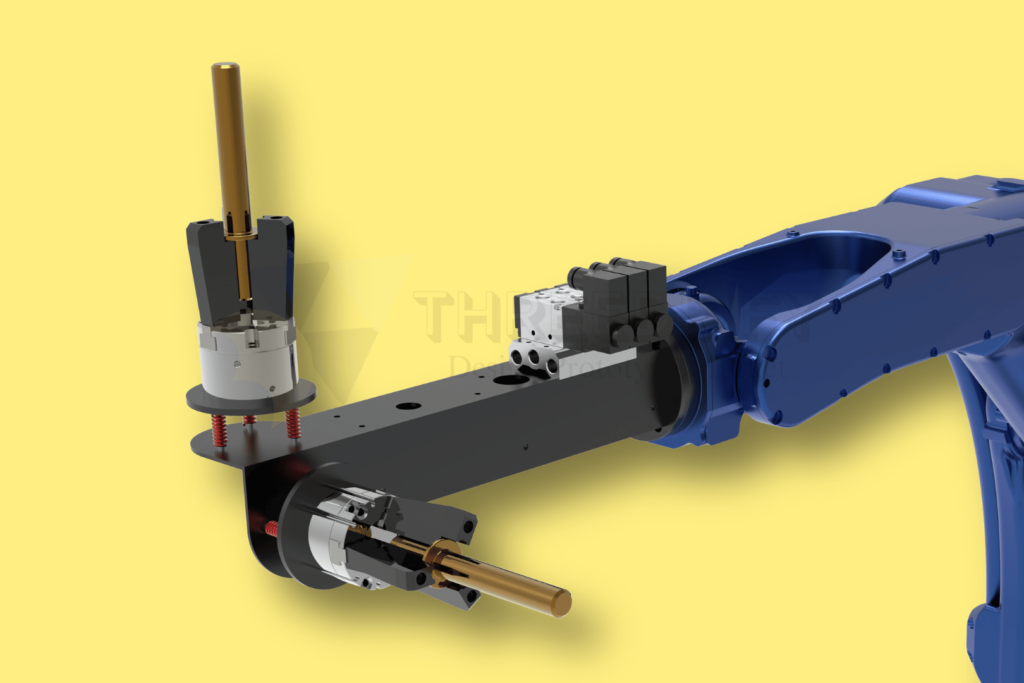

- Mechanical concepting and design

- Design for manufacturing

- 2D Drawings

- Manufacturing support

Project Summary

Problem Statement

Wiswig Factory needed an advanced end effector to support their GP12 robot in executing multiple automation and machining tasks. The challenge was to create a design that allows for easy jaw changes, enabling the use of different jaws for various products and operations. This flexibility was critical for their machining, grinding, and automation requirements. They approached us to design a high-performance solution that would enhance their automation process efficiency and precision.

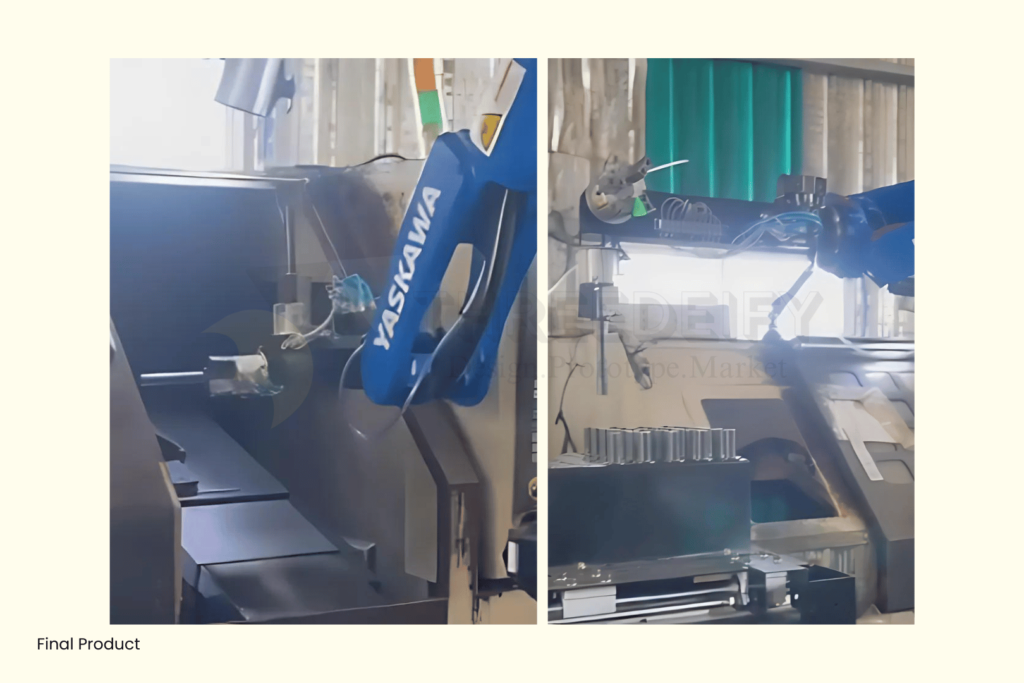

Delivery

Final Outcome

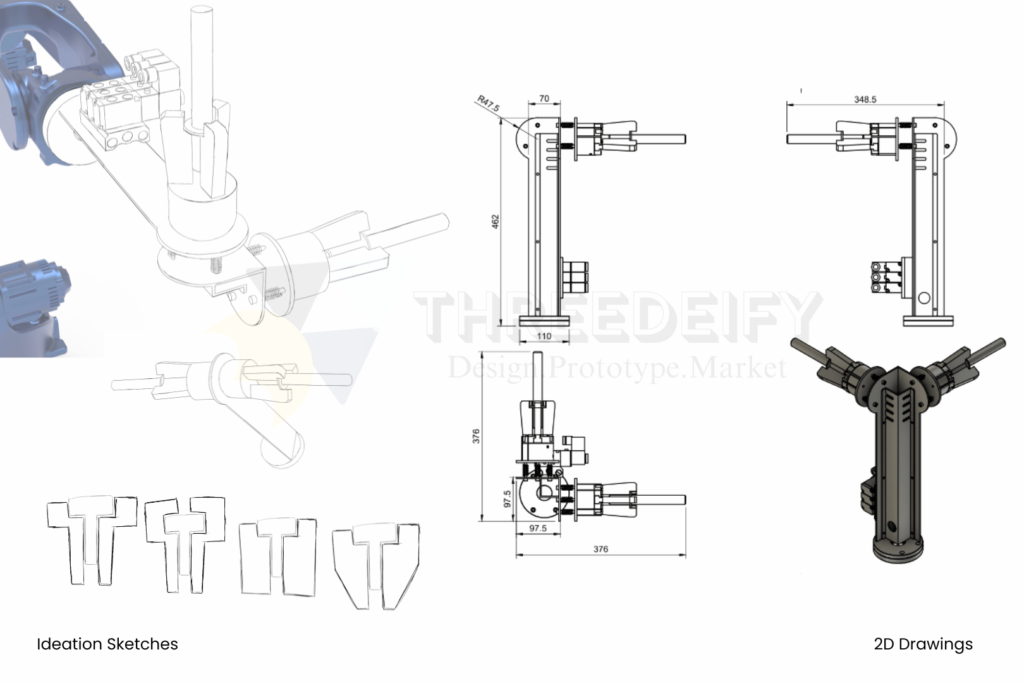

We collaborated with Wiswig Factory to design the HFCY50 GP12 End Effector, integrating two HFCY50 cylinders set at a 90-degree orientation. This innovative design allows for interchangeable three-jaw mechanisms, enabling the end effector to hold different products securely for a range of manufacturing processes. Our team provided mechanical concepting and design, design-for-manufacturing services, 2D drawings, and manufacturing support to ensure a seamless transition from concept to production. The final product improved the client’s operational flexibility, significantly increasing the range of tasks their GP12 robot could perform, while enhancing precision and adaptability.