Design

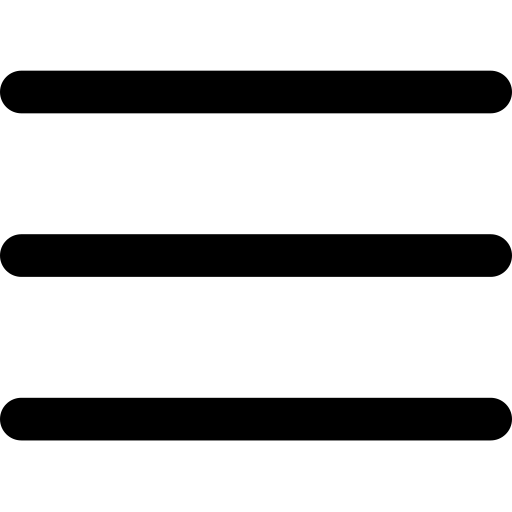

CVT Gearbox for EV L5 Auto Rickshaw

Timeline

2024

Client

Auto Speed

Services Provided

-

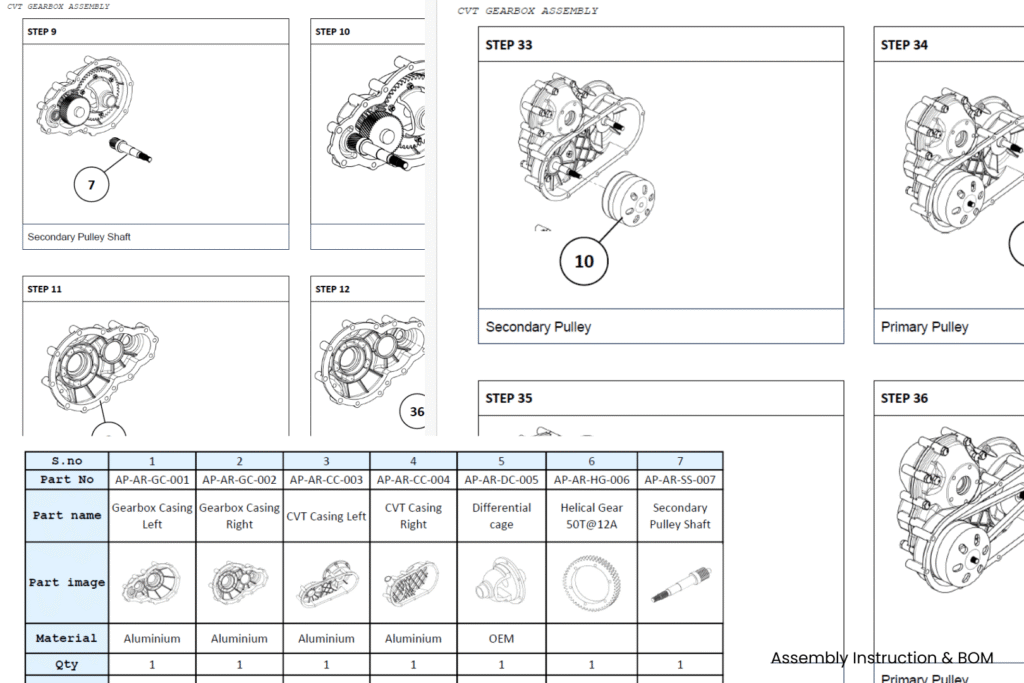

Gearbox architecture design for hybrid CVT and fixed-speed system

-

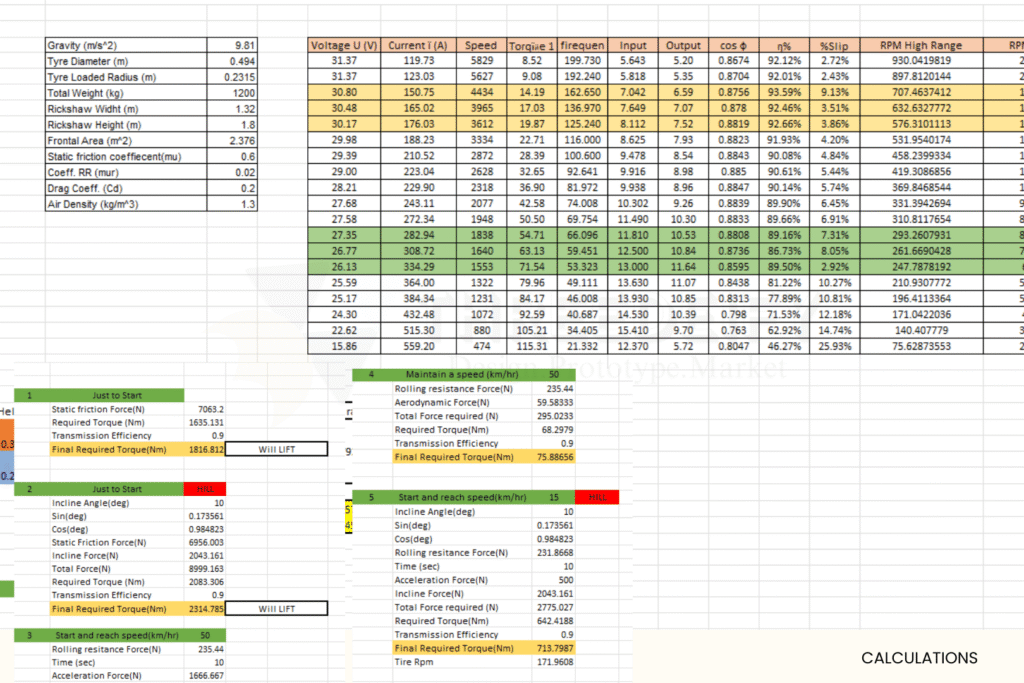

Performance calculations including gear ratios and CVT tuning

-

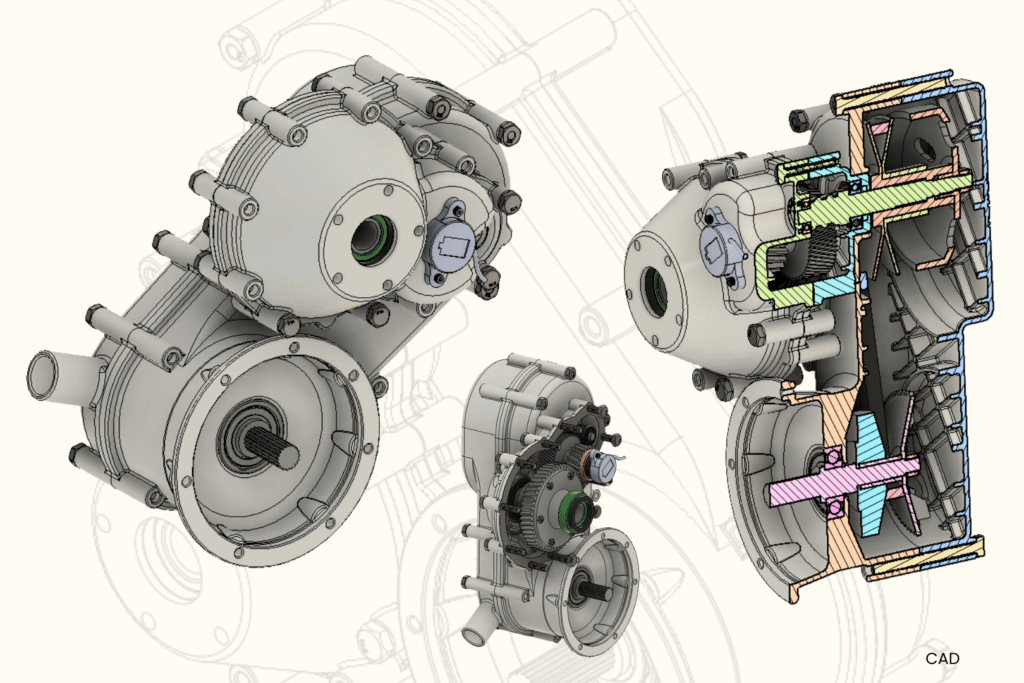

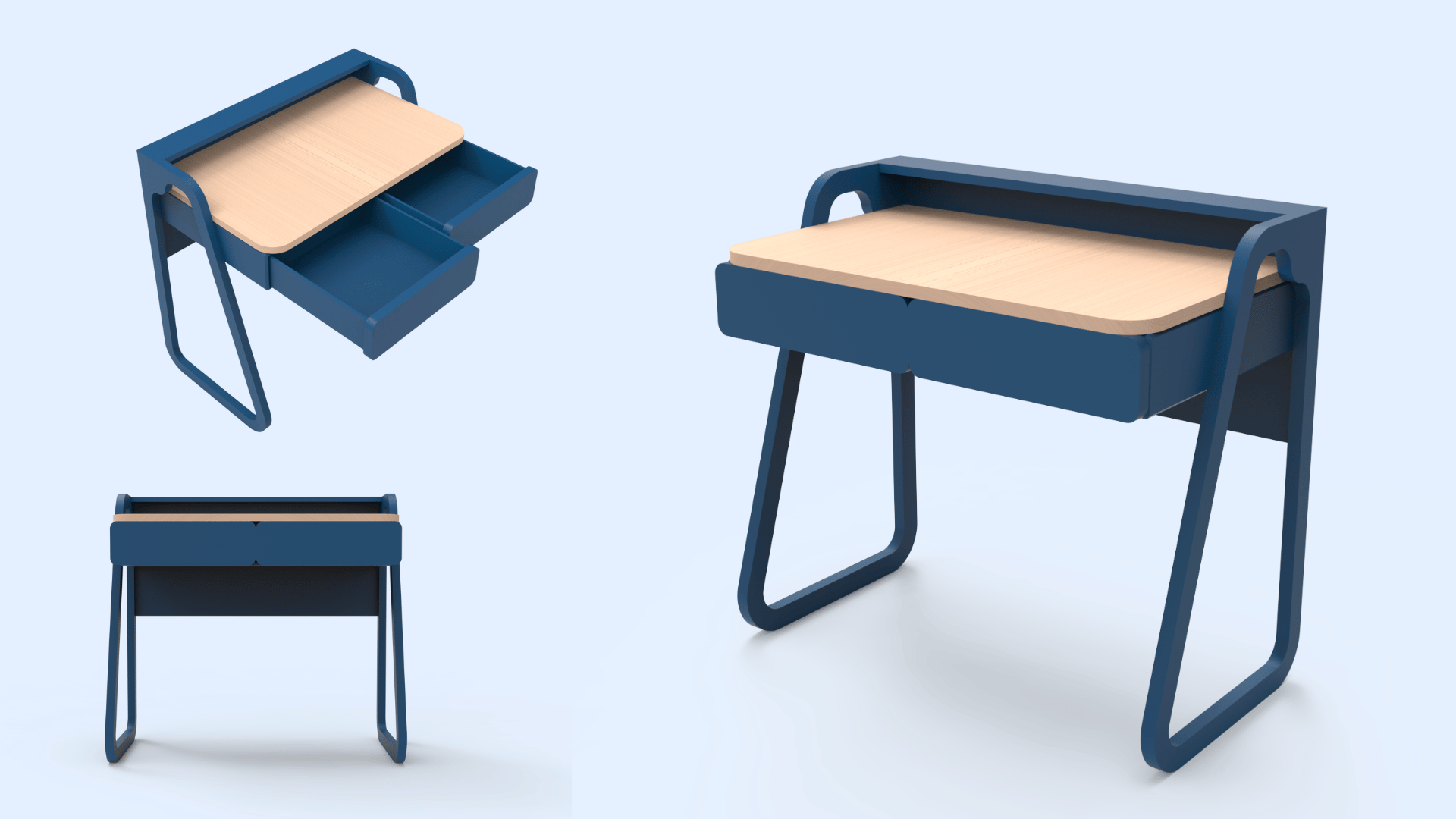

CAD modeling of all gears and mechanical layout

-

Space-optimized packaging to fit within EV rickshaw constraints

-

Manufacturing drawings and technical documentation

-

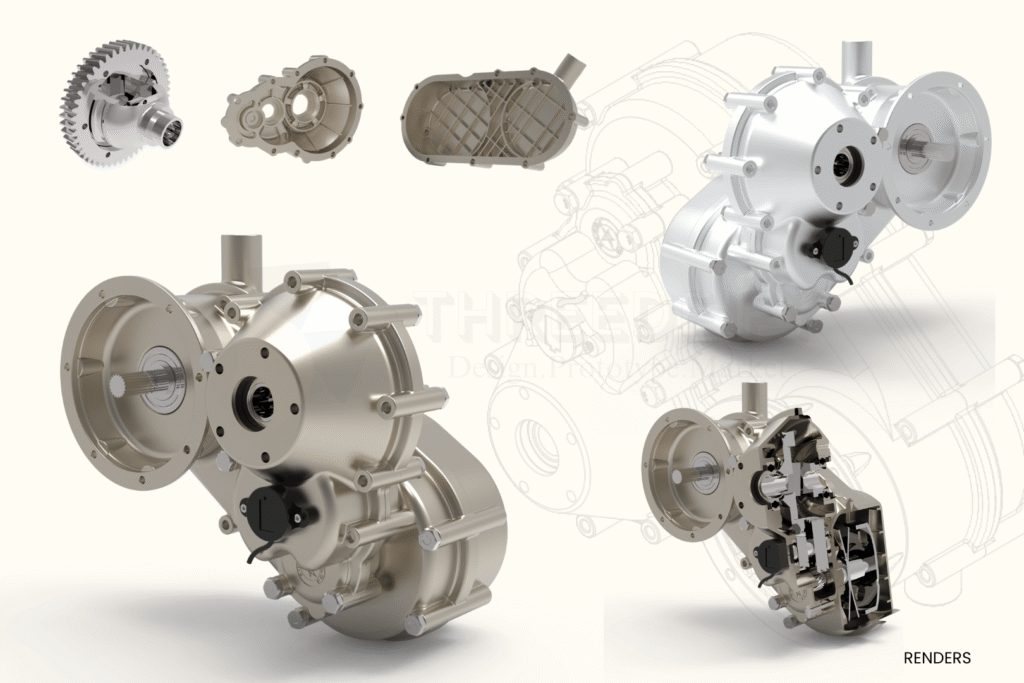

CNC machined prototype for real-world validation

Gearbox architecture design for hybrid CVT and fixed-speed system

Performance calculations including gear ratios and CVT tuning

CAD modeling of all gears and mechanical layout

Space-optimized packaging to fit within EV rickshaw constraints

Manufacturing drawings and technical documentation

CNC machined prototype for real-world validation

Project Summary

Problem Statement

Auto Speed approached us with a need to develop a custom gearbox system for their electric L5 category auto rickshaw. The goal was to achieve smooth acceleration, high torque during startup, and better energy efficiency — all while integrating seamlessly with the provided motor and battery specifications. The challenge was to create a hybrid transmission using both Continuously Variable Transmission (CVT) and fixed-speed gearing that could fit within the rickshaw’s compact chassis while optimizing performance and manufacturing feasibility.

Delivery

Final Outcome

We engineered a fully functional CVT + fixed gearbox system, tuned specifically for the torque and speed demands of an EV auto rickshaw. Starting with the client’s motor and battery specifications, we conducted all gear ratio calculations and CVT tuning to match the desired wheel output. The complete gear and housing layout was designed in CAD based on spatial limitations and manufacturability. The final gearbox housing was CNC machined for real-world validation. The result was a production-ready, high-efficiency transmission system that boosted starting torque and reduced current load, making Auto Speed’s vehicle more efficient and market-competitive.