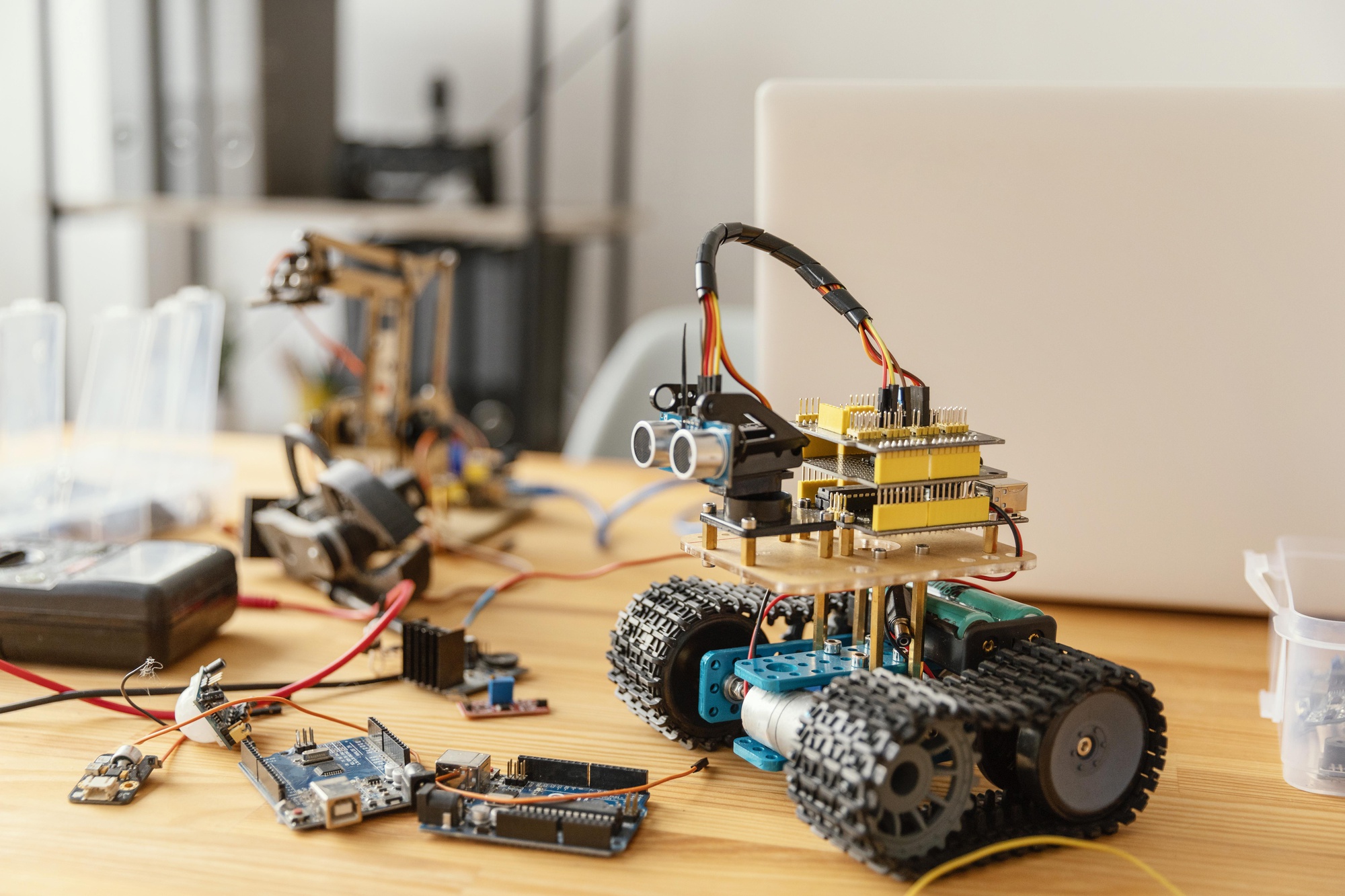

Validate product idea before building a prototype to avoid costly mistakes in hardware product development.

Physical products require significant investment in design, materials, tooling, and manufacturing. Unlike software, changes cannot be made instantly or cheaply once development moves forward. When teams skip early validation, they often discover critical problems only after time and money have already been spent.

Early validation helps reduce uncertainty. It allows you to test assumptions, confirm real demand, and make informed decisions before committing to prototyping. This guide explains how to validate a product idea in a clear, practical way before moving into hardware development.

Why You Must Validate Product Idea First

In hardware development, guessing is risky.

Once prototyping begins, even small changes can increase cost and delay timelines. Design changes may require new parts, different materials, or additional testing. Many teams only realize these challenges after they have already invested heavily in development.

When you validate product idea early, you reduce these risks. Validation helps businesses move forward with confidence instead of assumptions. It also improves alignment between product goals, user needs, and technical feasibility.

For startups working with limited budgets, validation is not optional. It is a safeguard that protects both time and capital while improving long-term success chances.

Step 1: Validate Product Idea by Defining the Problem

Every successful product starts with a clear problem.

Before thinking about features, design, or materials, identify the exact problem your product solves. Ask who experiences this problem, how often it occurs, and why current solutions are not sufficient. If the problem is not serious or frequent, users are unlikely to adopt a new hardware solution.

Clear problem definition is the foundation of product idea validation. Without it, even a well-designed prototype can fail in the market.

A strong problem statement also helps guide future decisions related to design, materials, and functionality.

Step 2: Validate Product Idea Through Market Understanding

Market understanding helps confirm whether real demand exists.

To validate product idea effectively, review existing hardware products or alternative solutions already available. Study customer reviews, complaints, and feature gaps. This research reveals what users like, what frustrates them, and where opportunities exist.

Understanding the market also helps you avoid building something that already exists without meaningful differentiation. Validation at this stage ensures your idea has room to compete and improve on current offerings.

Market research also helps define positioning, pricing expectations, and feature priorities early.

Step 3: Validate Product Idea by Talking to Users

Direct conversations with users provide insights that research alone cannot.

Speak with people who would realistically use your product. Ask how they currently solve the problem, what limitations they face, and what improvements they want. These discussions often uncover hidden needs or assumptions you may have missed.

Even a small number of honest conversations can help validate product idea assumptions and guide smarter design decisions later.

Listening carefully during these conversations often reveals more than surveys or data reports.

Step 4: Validate Product Idea Without a Physical Prototype

You do not need a physical prototype to test interest.

Simple sketches, diagrams, early CAD visuals, or concept renderings are often enough to explain the idea. These tools allow users to react to the concept and provide feedback without the cost of building hardware.

This approach helps you validate product idea early while keeping development flexible. At this stage, changes are easy, fast, and inexpensive compared to changes made after prototyping begins.

Early visual validation also helps designers and engineers align more effectively.

Turning early feedback into clear designs can be challenging. Having structured product design services at this stage helps teams translate ideas into practical concepts and avoid confusion later in development.

Turning early feedback into clear designs can be challenging. Having structured product design services at this stage helps teams translate ideas into practical concepts and avoid confusion later in development.

Step 5: Validate Product Idea by Testing Willingness to Pay

Interest alone does not guarantee success.

To properly validate product idea, you need to understand whether users are willing to pay for the solution. Ask direct questions about pricing expectations and compare similar products already on the market. This step helps separate curiosity from real buying intent.

Testing willingness to pay confirms whether your idea is commercially viable, not just technically interesting.

This insight is critical before committing resources to design and manufacturing.

Step 6: Review Feedback and Refine the Idea

After collecting feedback, patterns will begin to appear.

Some features may consistently receive positive responses, while others raise concerns. If users understand the problem and respond positively, your efforts to validate product idea are working. If feedback is mixed or unclear, refining the concept early is far less costly than changing it later.

Iteration at this stage strengthens the overall product direction and improves final outcomes.

Refinement is not failure it is part of smart product development.

Step 7: Decide When to Build a Prototype

Once validation signals are strong, it may be time to move forward.

When you successfully validate product idea before building a prototype, prototyping becomes a calculated investment instead of a risk. At this point, you have clearer requirements, stronger confidence, and better alignment with user needs.

If validation results are weak, further refinement is needed before proceeding. Rushing into prototyping without validation often leads to rework and wasted resources.

Good validation makes prototyping faster and more effective.

Common Mistakes When Skipping Product Idea Validation

Many startups underestimate the importance of validation.

Common mistakes include building a prototype too early, relying only on internal opinions, or assuming interest equals demand. These mistakes can lead to products that are technically sound but commercially unsuccessful.

Skipping validation also increases manufacturing risk and long-term cost.

Taking time to validate product idea helps avoid these pitfalls and creates a stronger foundation for development.

How Validation Supports Better Prototyping

Validated ideas lead to better prototypes.

When requirements are clear, prototypes are more focused and effective. Designers and engineers can work with better constraints, clearer goals, and fewer unknowns. This results in fewer iterations and more meaningful testing.

Validation ensures that prototyping efforts are aligned with real-world needs.

It also improves communication between product teams, engineers, and stakeholders.

Final Thoughts

Learning how to validate product idea before building a prototype is essential for successful hardware product development.

Early validation reduces risk, improves design decisions, and increases the chances of market acceptance. It allows teams to invest resources wisely and move forward with confidence.

At Threedeify, we help businesses validate ideas, design hardware products, build prototypes, and support early go-to-market efforts through startup marketing services. This structured approach helps teams move forward with clarity instead of assumptions.