Validate Product Idea Before Building a Prototype

Validate product idea before building a prototype to avoid costly mistakes in hardware product development. Learn how early validation helps reduce risk before design and prototyping.

December 11, 2024

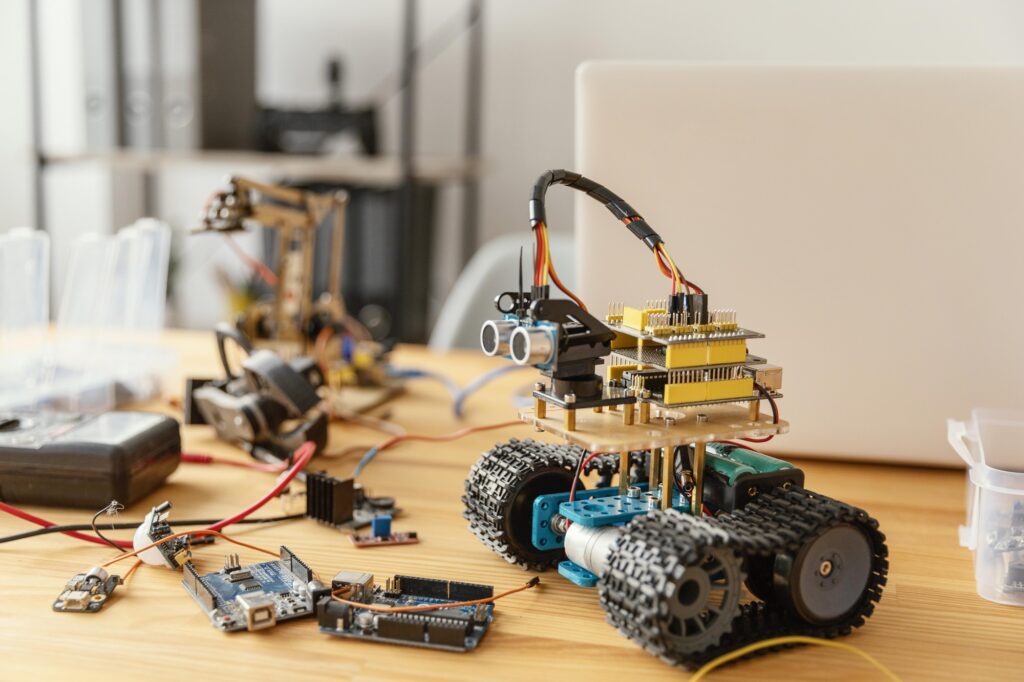

In today’s fast-paced market, electronic product design is no longer optional. Industries that thrived on traditional, low-tech products are witnessing a surge of competition from innovative players who are integrating embedded electronics to provide enhanced functionality and connectivity. If you’re a product developer who excels in mechanical, industrial, or consumer product design, adapting to this new reality is crucial to retaining your market position.

This guide is designed for developers stepping into the world of embedded electronic design. It covers the basics of integrating electronics into your products, the benefits, and practical steps to stay ahead.

According to a recent study, the embedded electronics market is projected to grow to $116 billion by 2025, driven by increasing adoption of smart technology in everyday products. [Source]

Incorporating embedded electronics is about more than just “adding tech.” It enhances product capabilities, creates unique user experiences, and keeps you relevant in a connected world. Here’s why your business should consider this shift:

Example: Traditional door locks have evolved into smart locks that offer fingerprint scanning, mobile access, and voice control. Companies that ignored this trend fell behind.

For businesses unfamiliar with electronic product design, the transition can be daunting. Some common challenges include:

Ignoring these challenges can result in products that are unreliable or fail to meet market needs.

At Threedeify, we specialize in electronic product design and prototyping, helping businesses transform traditional products into market-ready smart solutions. Here’s how we tackle the challenges and ensure your success:

As markets evolve, integrating embedded electronics into your products is no longer optional — it’s a necessity. Electronic product design enhances functionality, improves user experience, and ensures you stay ahead of the competition. By understanding the challenges and partnering with Threedeify, you can confidently upgrade your products, tackle complexity, and lead your industry with innovation.

Was this article helpful?

Related Articles

Validate product idea before building a prototype to avoid costly mistakes in hardware product development. Learn how early validation helps reduce risk before design and prototyping.

Budget constraints can make or break your product development process. Learn how to manage your budget effectively and still deliver a market-winning product.

Prototyping is a critical step in product development, helping you test, refine, and validate ideas before full-scale production. Discover why every successful product starts with a prototype.